Vacuum generators

The creation of vacuum is possible with different technical solutions.

1. Dry-running vacuum pumps are using self-lubricating vanes to have a dry-running system. They are very compact, powerful and low-maintenance vacuum generators. The rotary vane principle is known to be very robust and durable. They are particularly suitable for dense transport goods and can be installed in almost any position.

Functional principle: Vanes are loosely inserted into the slots of the rotor, which is eccentrically mounted in a cylinder. These are pressed against the cylinder wall by centrifugal force and divide the compression chamber into several chambers. Air flows into the chambers from the inlet channel. The chamber volume decreases towards the air outlet duct and the trapped air is compressed and pushed out.

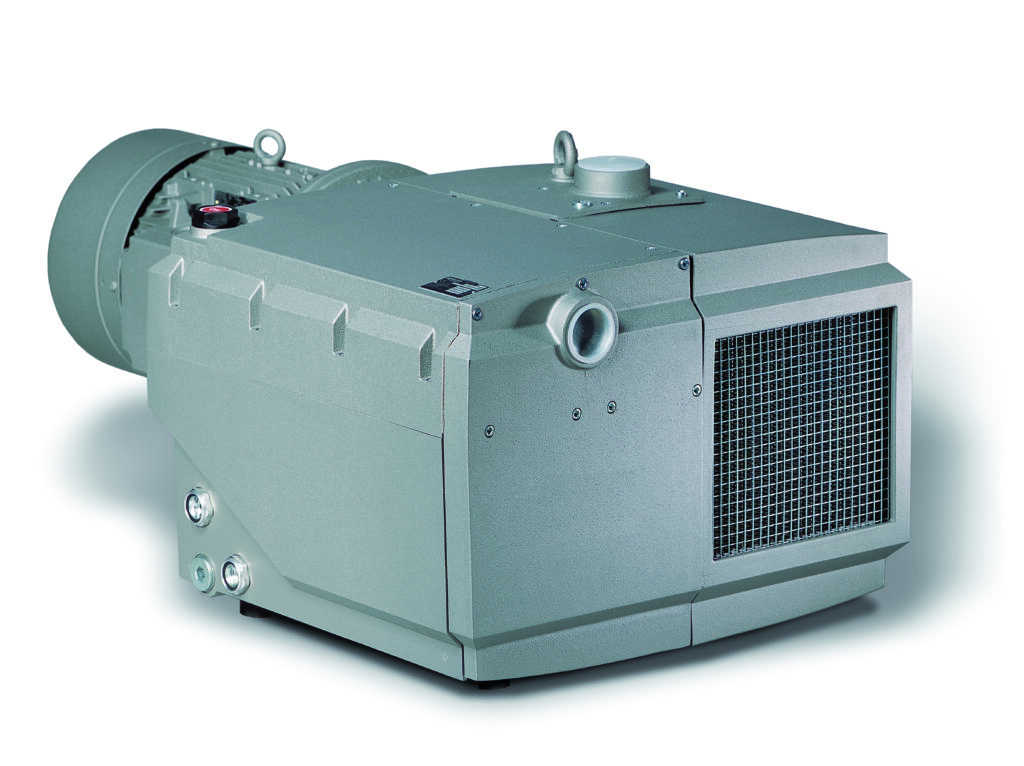

2. Oil-lubricated vacuum pumps have a simple design with just one shaft and direct drive results in a robust, long-lasting vacuum pump with low maintenance and operating costs. Additional accessories can be easily added. The standard oil circulation lubrication with integrated oil cooler and the cover also minimize noise emissions

Functional principle: The vanes are sealed by the metered oil supplied and conveyed. Check valve and efficient oil separation are integrated into the pump. The oil suction controlled by a float valve enables the use of the vacuum pumps even in rough vacuum operation. Optional water cooling significantly extends the service life of the oil, even under difficult environmental conditions.

3. Vacuum blowers (side channel blowers) deliver a high-volume flow. They are used wherever large amounts of air need to be extracted. Vacuum blowers are very suitable when it comes to sucking in air-permeable materials such as cardboard boxes, paper sacks or porous chipboard.

Functional principle: A rotating impeller accelerates the air several times and thereby compresses it. At the outlet, the compressed air is expelled through a silencer. A negative pressure is created at the fan inlet and a lot of air can flow in.

4. Vacuum ejectors: In contrast to electric vacuum generation with a pump or blower, ejectors are independent of the power grid. Only a compressed air connection is required. Ejectors create a vacuum of up to 90% with a lower volume flow. However, the volume flow can be increased by using a multi-chamber ejector.

Functional principle: Compressed air flows through a nozzle into the ejector. The narrowing of the cross-section in the nozzle increases the flow speed of the air. After the nozzle, the air enters a chamber. This creates a vacuum and air is sucked in through the intake opening. The compressed air and the intake air are expelled as exhaust air. Multi-chamber ejectors consist of several individual ejectors connected in series. The exhaust air is led to the compressed air inlet of another ejector. In this way the volume flow can be increased.